oferta

Machines for print application and decorations of parts made of plastic, glass or other materials using hot stamping technology.

The process is based on stamping the printed pattern on the surface of part with a stamp or roller and a specialized foil covered with a coloring layer (including metallic gloss). The prints are permanent immediately after their execution.

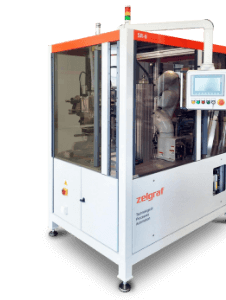

Hot stamping machines equipped in one head for manual feeding of parts by operator.

Standard machine equipped:

‣ Mitsubishi PLC controller,

‣ side mounted control panel with 7" touchscreen,

‣ LED signal lamp (3-colours) with an acoustic signal,

‣ upper safety guards made of aluminum profiles and polycarbonate,

‣ two-hand control,

‣ structure made of anodized aluminum profiles,

‣ print head (roll-on or up-down) with pneumatic drive with a maximum pressing force up to 12 kN,

‣ automatic foil rewinding/winding system,

‣ air preparation unit with pressure sensor.

All our machines are covered by a one-year warranty, service and EC declaration of conformity

Hot stamping machines equipped with one or more heads, designed to work mainly in automatic mode.

APO Pro model allows to make prints in several techniques and technologies, as well as to perform other technological operations within one cycle and within one machine.

Standard machine equipped:

‣ Mitsubishi PLC controller,

‣ side mounted control panel with 7" touchscreen,

‣ LED signal lamp (3-colours) with an acoustic signal,

‣ upper safety guards made of aluminum profiles and polycarbonate,

‣ structure made of powder-coated aluminum profiles,

‣ print head (roll-on or up-down) with pneumatic drive,

‣ automatic foil rewinding/winding system,

‣ air preparation unit with pressure sensor,

‣ LED workstation lighting

All our machines are covered by a one-year warranty, service and EC declaration of conformity

Hot stamping machines equipped with one or two heads, designed to work mainly in automatic mode.

Unlike the APO, the APOS / APOSM are equipped with a rotary module for vertical transport of parts.

Standard machine equipped:

‣ Mitsubishi PLC controller,

‣ arm-mounted control panel with 7" touchscreen,

‣ LED signal lamp (3-colours) with an acoustic signal,

‣ upper safety guards made of aluminum profiles and polycarbonate,

‣ structure made of powder-coated aluminum profiles,

‣ print head (roll-on or up-down) with pneumatic drive,

‣ automatic foil rewinding/winding system,

‣ vertical rotary module,

‣ air preparation unit with pressure sensor,

‣ LED workstation lighting

All our machines are covered by a one-year warranty, service and EC declaration of conformity

Hot stamping machines

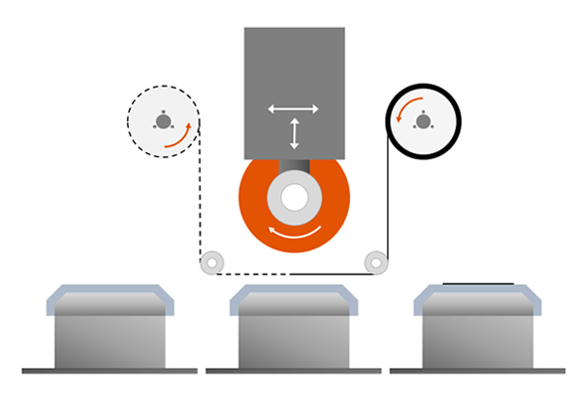

The print with the use of a rotating aluminum-silicone roller. This technique is mainly used for full-surface printing or for printing of continuous patterns, such as stripes.

Hot stamping machines

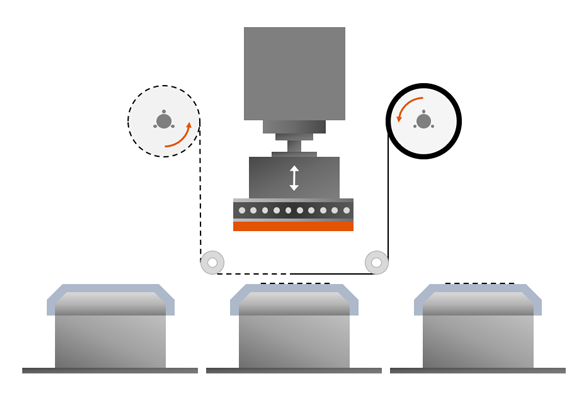

The print is made using a hot stamp (flat or shaped). The pattern from the stamp is impressed through the foil on part, by the printing head. There is also a variation of Up-down for printing on the side surfaces of round details, based on rolling the part under flat stamp (linear or non-linear in the case of conical surfaces)

Hot stamping machines

Machines with several print heads (usually from 2 to 4), to increases the efficiency or to allow more complex prints - e.g. multi-color. It is also possible to combine hot stamping technique (Roll-on and Up-down) with each other, and with other printing technologies, such as screen printing.

Our qualified experts are ready to provide you with all necessary information

Feel free to contact us